📁 Market

AI generated

Bosch’s €2.9 billion AI investment and shifting manufacturing priorities

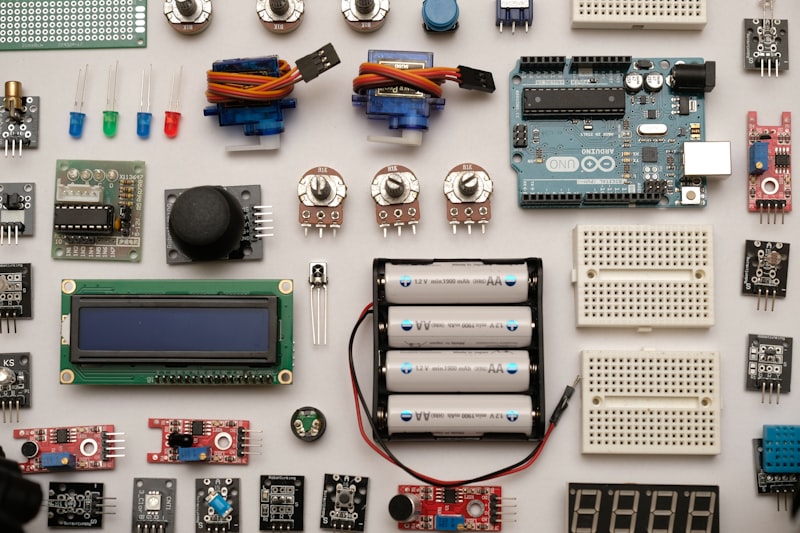

Bosch is boosting the integration of artificial intelligence (AI) into its manufacturing processes, with a planned investment of €2.9 billion by 2027. The initiative aims to optimize production, supply chain management, and perception systems.

## Early detection of production problems

Bosch uses AI models to analyze data from cameras and sensors, with the goal of identifying quality defects early. This approach allows intervention during the production process, reducing waste and the need for rework.

## Predictive maintenance

The company also applies AI to equipment maintenance, analyzing data related to vibration, temperature, and usage to predict potential failures. This allows repairs to be planned proactively, minimizing unplanned downtime and extending the useful life of machines.

## Adaptable supply chains

The investment also includes improving the supply chain, with AI systems capable of forecasting needs, tracking components, and adjusting plans based on changing conditions. This is particularly important in a context of ongoing disruptions and transport delays.

## Edge computing

Much of this work takes place via edge computing, allowing systems to respond in real time and operate even in the event of connectivity problems. Edge computing also limits the amount of sensitive data leaving the production site.

## Scaling beyond the pilot phase

This large-scale investment is significant because many companies remain stuck in the pilot phase with AI. Widespread implementation requires funding, skilled staff, and a long-term commitment.

Bosch's approach considers AI as a support tool for workers, capable of handling complexity that humans cannot handle alone. This reflects a broader shift in the industry, where AI is increasingly seen as a basic infrastructure.

💬 Commenti (0)

🔒 Accedi o registrati per commentare gli articoli.

Nessun commento ancora. Sii il primo a commentare!